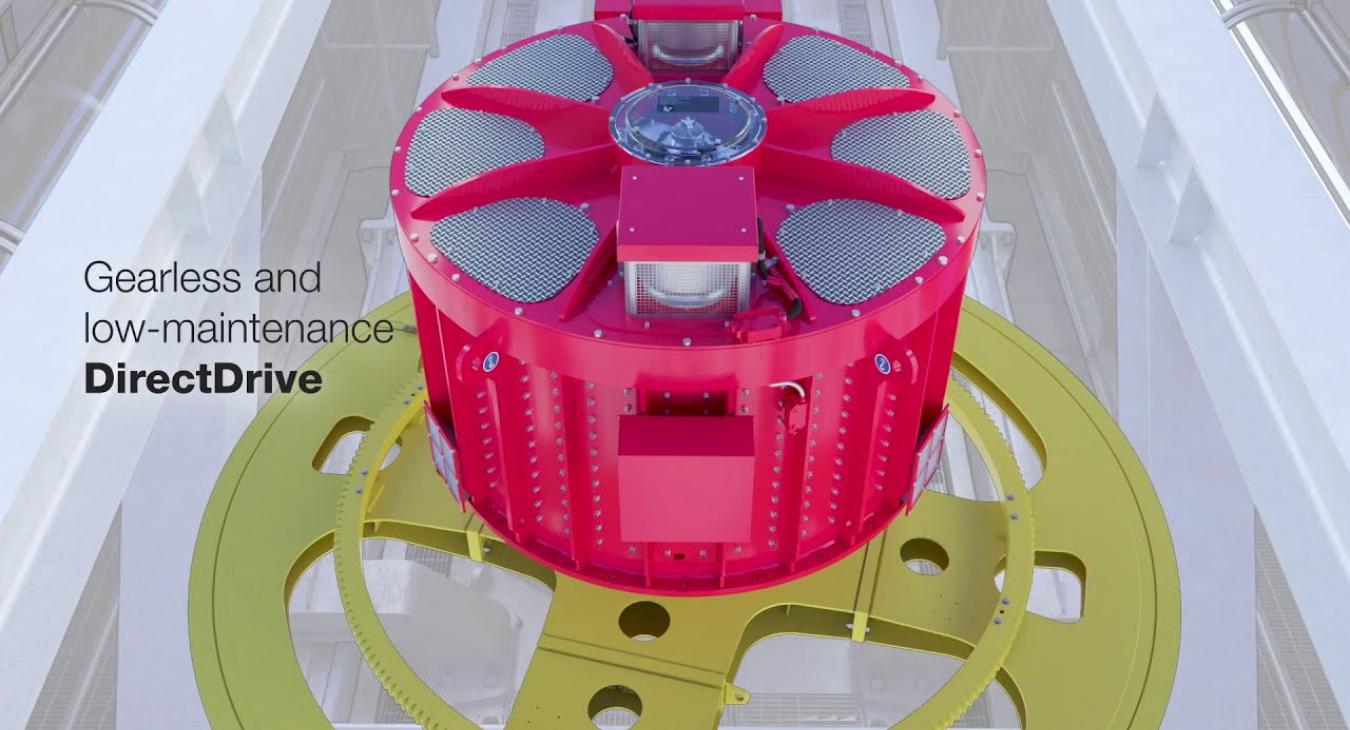

LEITNER DirectDrive

Reduces energy consumption and can be used as a generator in wind power installations.

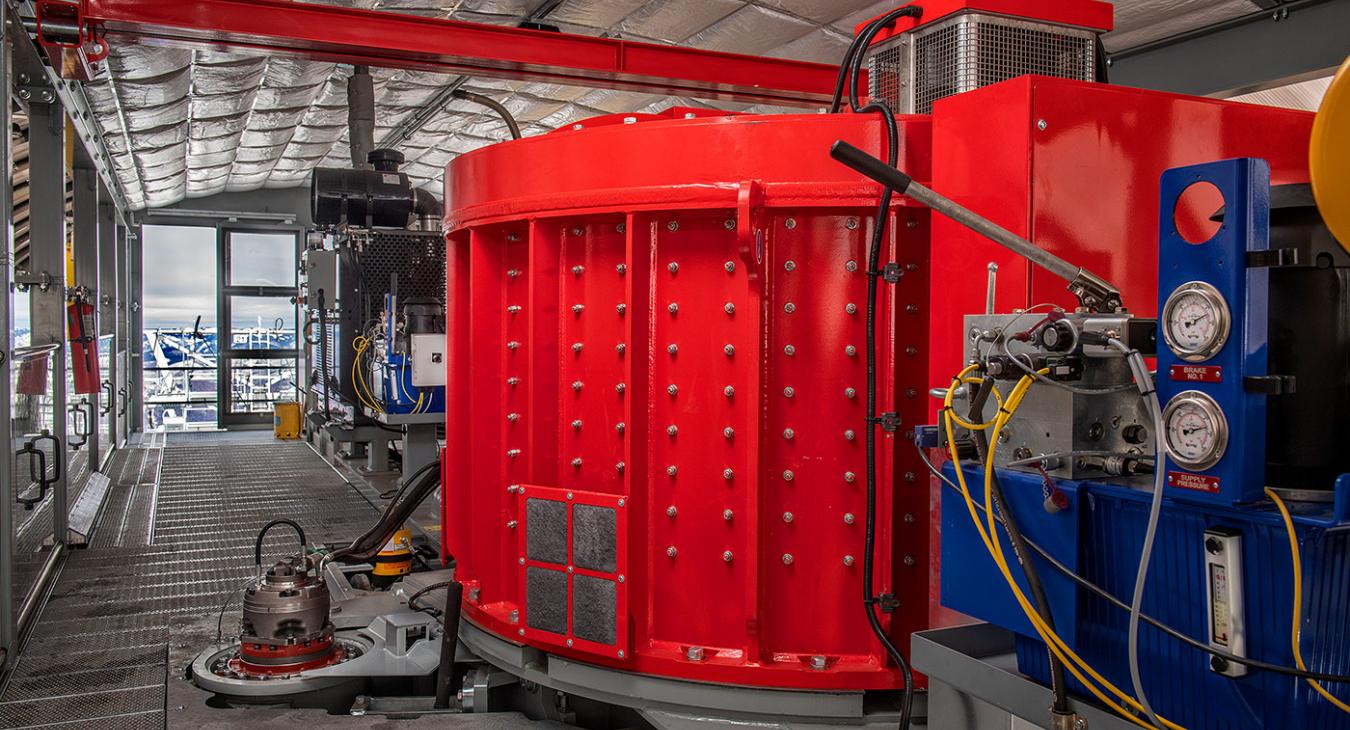

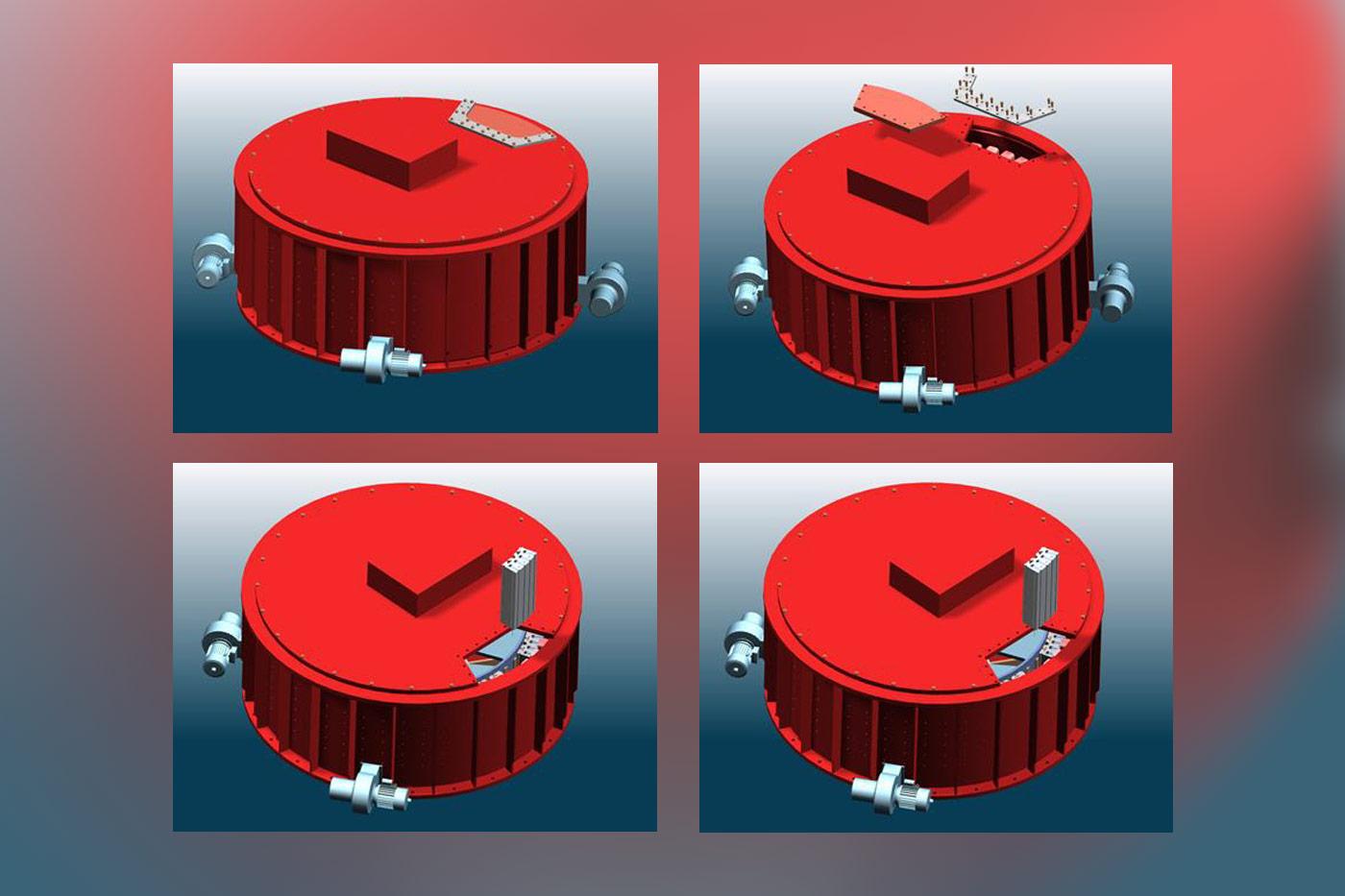

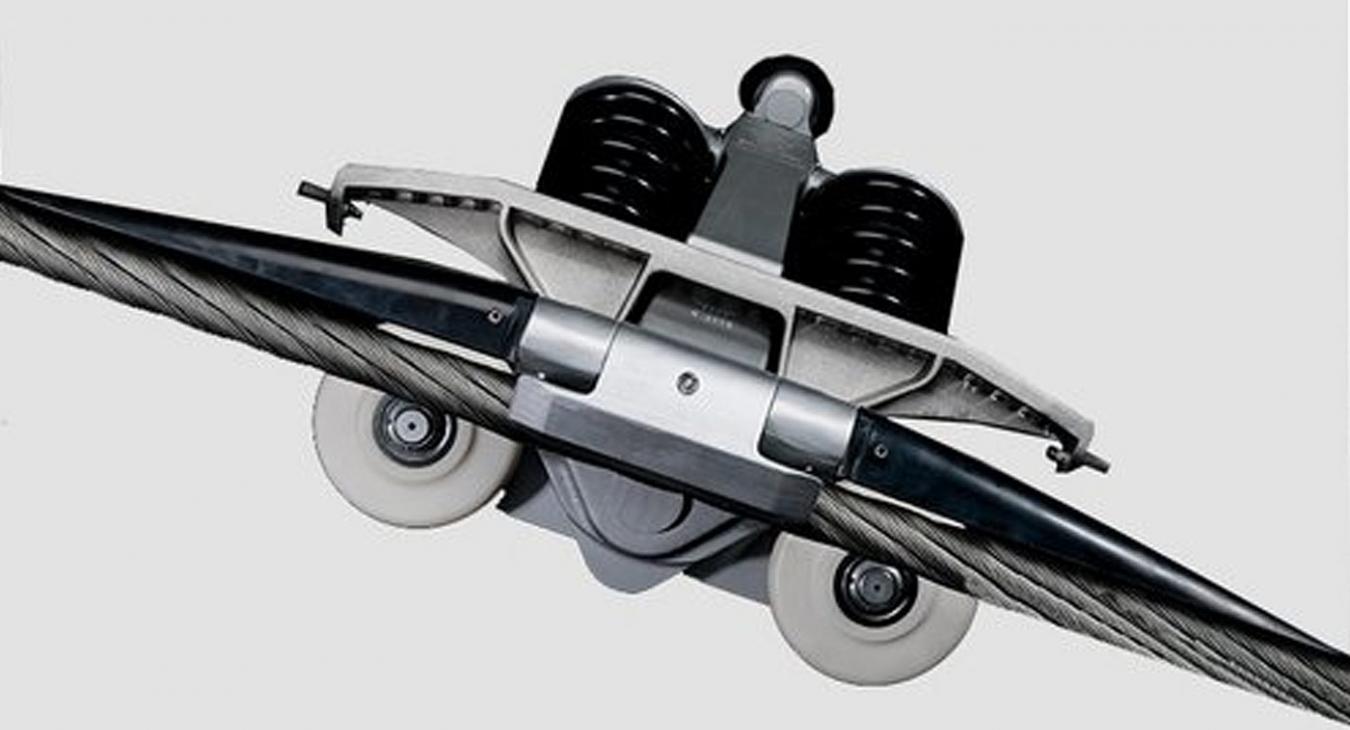

The LEITNER DirectDrive – a gearless drive system for ropeways – is unparalleled across the world. It consists of a low-speed synchronous motor, and its output shaft is directly linked to the pulley wheel. Foregoing a complex gear system has considerable advantages in terms of its operation.

LEITNER ropeways’ globally unique DirectDrive succeeds in significantly reducing energy consumption, and can be used as a generator in wind power installations as well. It is more reliable than other systems of a comparable nature, as well as more comfortable for passengers thanks to its lower noise emissions.

LEITNER DirectDrive installations will provide an answer to fundamental questions of the future. In the meantime, the LEITNER Group can look back proudly on its impressive backlist: more than 200 ropeways and 275 wind power facilities work using this technology. Currently we now have seven lifts in the USA being powered by this technology.

Sound pressure level:

Classic drive: 88 92 dB (A)

DirectDrive: 73 75 dB (A)

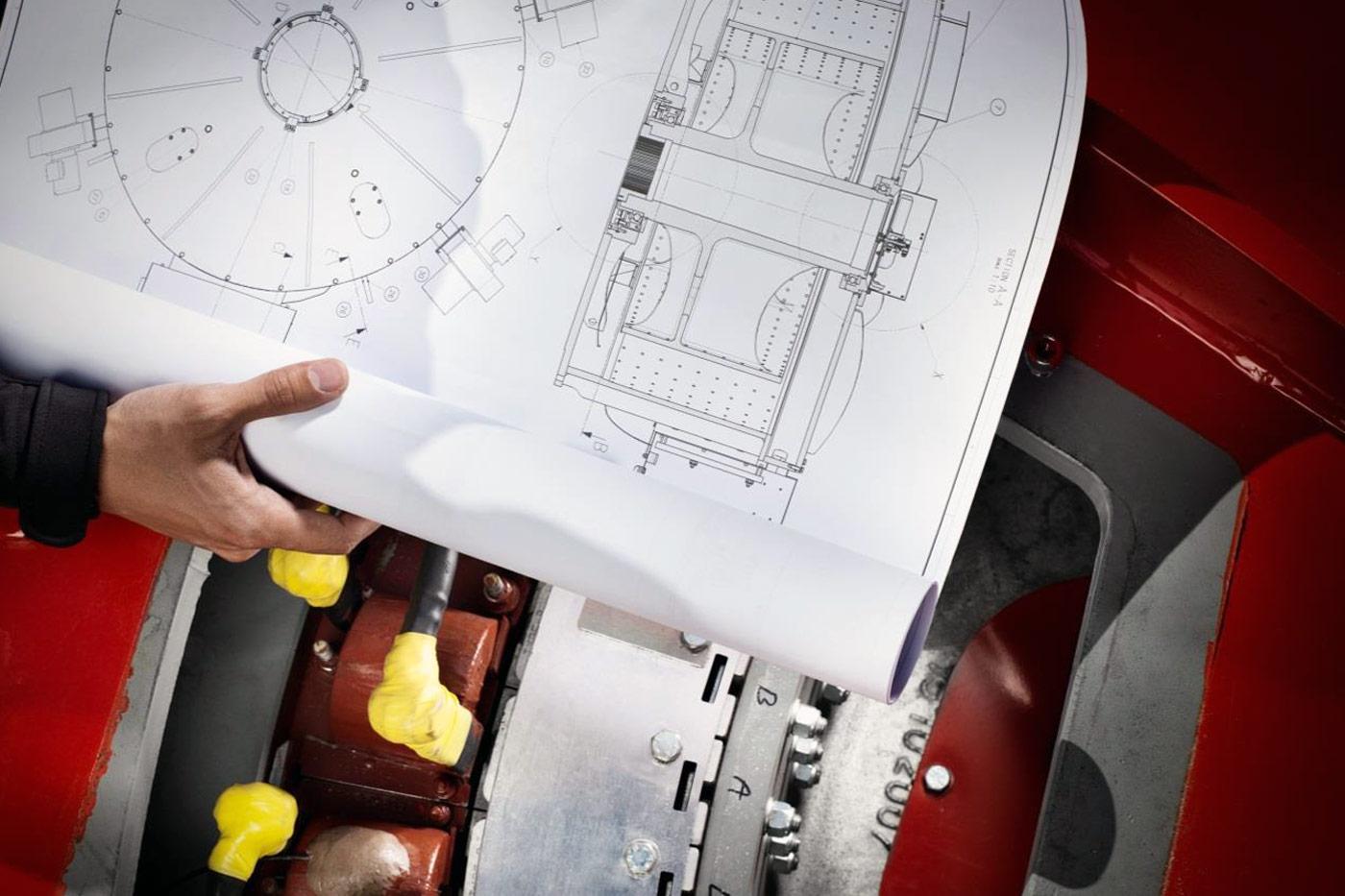

- The efficiency factor of an AC electric motor and a DirectDrive are nearly the same (about 94%).

- The efficiency factor loss of 5% caused by the gearbox will be avoided with the DirectDrive.

- New measures regarding this where made in 2011 according to EN60034 2.

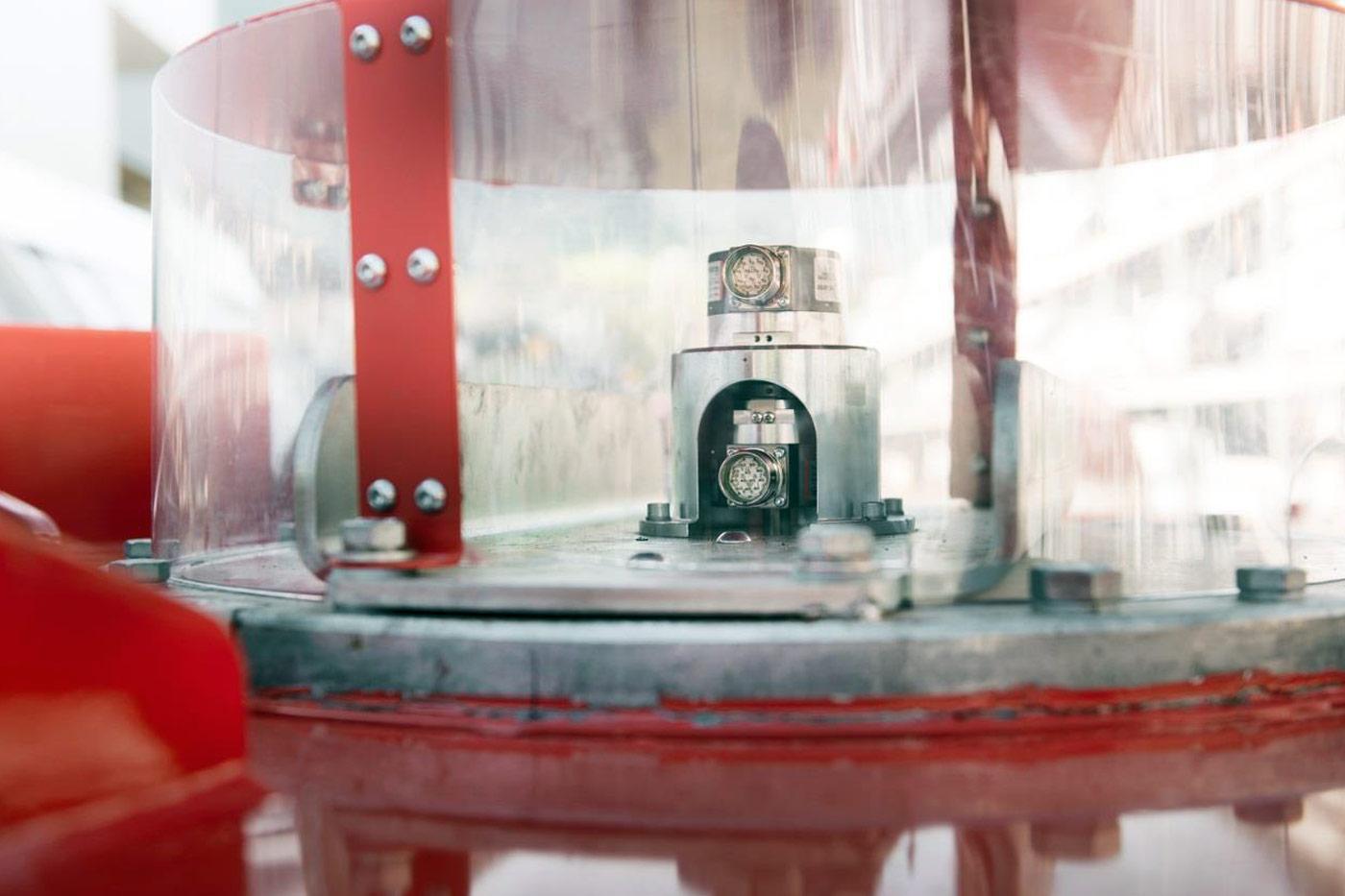

If the traditional drive system has a problem, especially in the gearbox, the ropeway stops.

With DirectDrive the operation of the drive continues even if some of its parts are damaged.

The LEITNER DirectDrive runs slower and consists of fewer parts than the traditional drive. This guarantees fewer problems and consequently higher availability.

Thanks to the absence of a complex gearbox in the ropeway system, the DirectDrive doesn’t use any oil.

Gearbox LP300

- Required oil quantity: 92.5 gallons (350 liters).

- Change every 6,000 operating hours.

- A DirectDrive operating 1,500 hours per year in a span of 20 years can generate the savings of 462 gallons (1,750 liters) of oil.